Galvanized Coil: Driving Durability and Innovation in Steel Applications

Release time:

2025-08-15

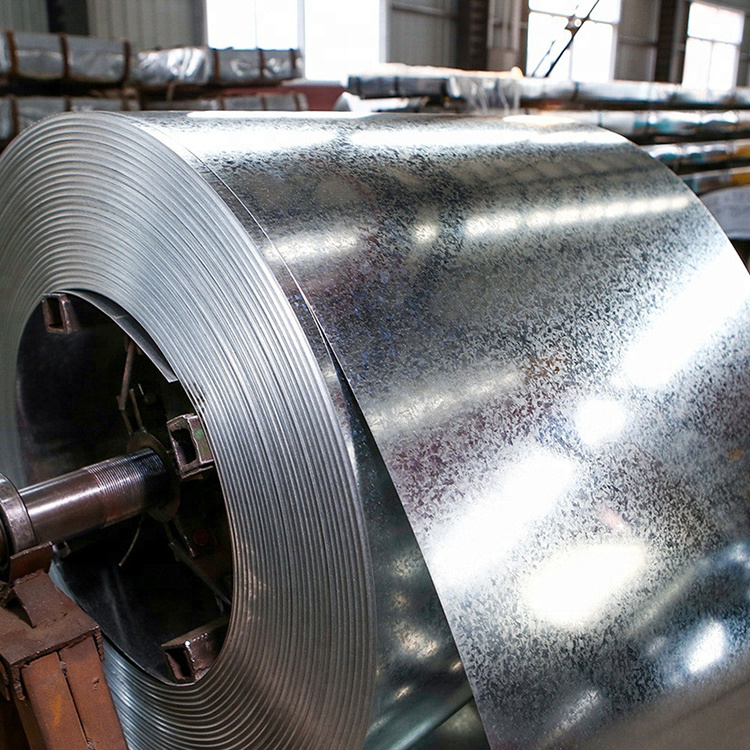

Galvanized coil, a key product in the steel industry, has become indispensable in modern construction, automotive manufacturing, and household appliances. Produced by coating steel sheets with a layer of zinc, galvanized coils offer excellent corrosion resistance, ensuring longevity even in harsh environmental conditions. This protective layer not only prevents rust formation but also enhances the mechanical strength of the underlying steel, making it suitable for structural applications where both durability and performance are critical.

The production process of galvanized coils typically involves hot-dip galvanization or electro-galvanization. In hot-dip galvanization, steel coils are passed through molten zinc, forming a metallurgical bond that ensures uniform coverage and long-lasting protection. Electro-galvanization, on the other hand, involves the deposition of a thin zinc layer using an electric current, producing coils with a smoother surface finish suitable for aesthetic applications, such as household appliances and decorative panels. The choice of galvanization method depends on the intended use, environmental exposure, and cost considerations.

Galvanized coils have a wide array of applications across industries. In construction, they are used in roofing, wall panels, and structural components, providing both strength and resistance to corrosion. In the automotive sector, galvanized steel helps prevent rust in vehicle bodies and chassis, improving vehicle lifespan and safety. Additionally, galvanized coils are essential in manufacturing household appliances such as refrigerators, washing machines, and HVAC systems, where both appearance and resistance to moisture are crucial.

Innovation in galvanized coil technology continues to improve its performance. Advanced coatings, including zinc-aluminum alloys and chromate-free options, offer enhanced corrosion protection while meeting environmental regulations. Furthermore, customized coil dimensions, surface finishes, and coatings allow manufacturers to tailor products to specific applications, improving efficiency in production and assembly. The integration of digital monitoring and quality control in production lines also ensures consistent quality and reduces material waste.

The demand for galvanized coils is influenced by both industrial growth and environmental awareness. As industries strive for sustainable and durable materials, galvanized coils stand out for their recyclability, energy efficiency in production, and long service life. By combining strength, corrosion resistance, and versatility, galvanized coils continue to play a vital role in modern industrial applications, supporting innovation while meeting the demands of contemporary engineering and construction practices.

Latest News

Square Steel HSS Tube Applications and Benefits

Square steel HSS tubes offer strength, versatility, and efficiency, widely used in construction and engineering for durable, cost-effective structures.

2025-08-13

Carbon Steel H Steel Shapes in Construction

Carbon steel H steel beams offer high strength, durability, and versatility, supporting modern construction with cost-effective and sustainable solutions.

2025-08-13

Exploring the Benefits of Galvanized Sheets in Modern Construction

Exploring the Benefits of Galvanized Sheets in Modern Construction In the ever-evolving landscape of modern construction, materials play a pivotal role in ensuring structural integrity, longevity, and cost-efficiency. Among the myriad of options available, **galvanized sheets** have emerged as a preferred choice for builders, architects, and contractors alike. This article delves into the numerous

2025-08-11

Understanding Galvanized Sheets: Essential Insights for the Metallurgical and Energy Industries

Galvanized sheets, commonly known for their corrosion-resistant properties, play a crucial role in various industries, including metallurgy and energy. The process of galvanization involves coating steel or iron with a layer of zinc, which protects the underlying metal from rust and degradation. This makes galvanized sheets a preferred choice in environments where exposure to moisture and corrosiv

2025-08-09